At last, a smarter and more efficient way of keeping your facilities cool and comfortable

The most advanced suite of oil-free centrifugal chillers.

Smardt chillers are 100% oil-free

At Smardt, all we do is oil-free chillers. Nothing else. Manufacturing and supporting oil-free chillers have been our sole business for almost 20 years. When you rely on Smardt, you’re dealing with the experts in oil-free chiller technology.

Patented chiller innovations

Technology breakthroughs that deliver performance

Proprietary designs, expertise, and technologies give our best-selling oil-free centrifugal chillers more consistent performance. Proven for decades with thousands of Smardt oil-free chillers in operation worldwide.

Lowest total cost of ownership

Slashes your utility bills

Our customers often achieve payback in under two years as energy efficiency increases, contamination is virtually eliminated, and maintenance time and labor are significantly reduced due to the lack of lubrication system requiring down-time for inspections or repair. There are no expensive metal parts that wear out and need replacing.

Customized solutions

A perfect fit for your application and building

Advanced features

Takes performance to the next level

Minimize downtime

Be back up and running in seconds

Product innovation

The most comprehensive selection of high-performance oil-free chillers.

The most comprehensive selection of high-performance oil-free chillers.

Air-cooled oil-free chiller

T-Class

40 to 500 tons

(140-2,1760 kW)

The Smardt air-cooled range offers the smallest footprint, the quietest operation, and the highest air-cooled operating efficiencies in the market. Standard Smardt air-cooled chillers are over 70% lower in sound power than a standard screw machine.

- Highest operating efficiency.

- Smallest footprint.

- 70% quieter operation.

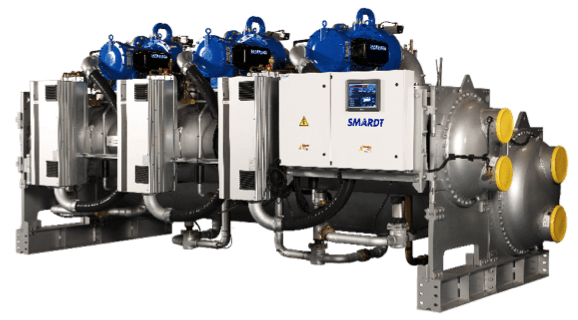

Water-cooled oil-free chiller

V-Class

350 to 3600 tons

(1,231 kW-12,66 MW)

Smardt’s V-Class range brings new levels of efficiency, reliability and turn-down to the large water-cooled chiller market – now up to 3600 TR (12.6MW).

- Our largest water-cooled oil-free chiller range

- Low kW/TR at low temperatures.

- Inbuilt redundancy with multiple compressor design

Water-cooled oil-free chiller

T-Class

45 to 1600 tons

(211-4,200 kW)

Smardt’s T-Class water-cooled chillers offer class leading performance and are available in a variety of different configurations to suite you project

- Highest operating efficiency.

- Smallest footprint.

- Inbuilt redundancy.

Evaporatively cooled oil-free chiller

E-Class

45 to 530 tons

(160-1,860 kW)

The E-Class chiller is Smardt’s adiabatic cooling system. Cross-fluted evaporative pads are situated on the outside of the coils. Separated from the coil surface, these pads are designed to be saturated with treated water, and the pads also provide protection for the coils.

- More efficient than air-cooled chillers

- High efficiency even in warm, dry climates

- No cooling towers or risk of Legionella

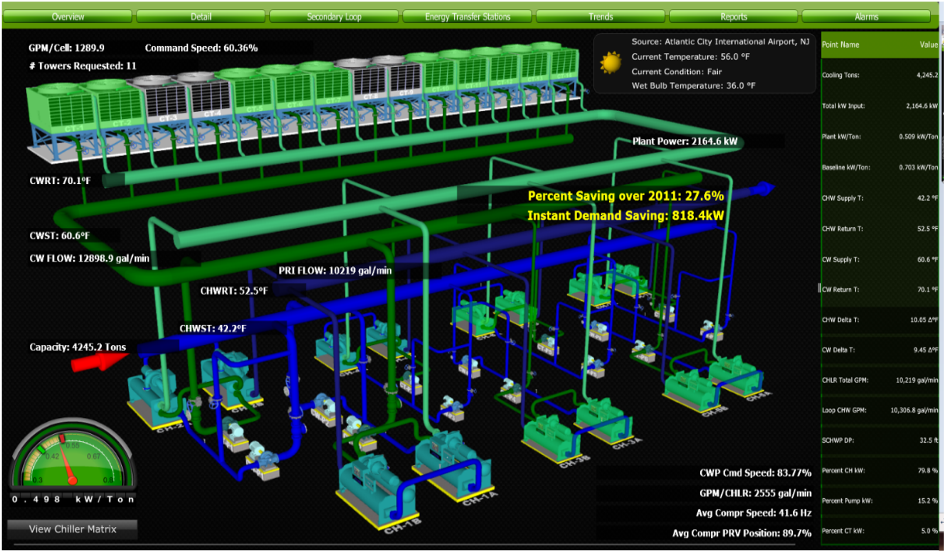

Plant optimization

CPECS

Plant optimization

Using pioneering experience with Turbocor oil-free compressor technology, chiller plant thermodynamics, plant design and control, Kiltech’s Central Plant Energy Conversation System (CPECS) ensure end-users get the absolute most out of their plant.

- Live simulation optimization methodology

- Real-time equipment curve comparison

- Efficiency improvements of 20-70%

Specialization

Smardt-OPK

Special products

With over 35 years of experience and expertise, the Smardt Special Products group can help with your unique refrigeration and cooling applications.

- Heat exchangers/pump stations

- Containerized packaged plants

- Bespoke heat pumps and chillers