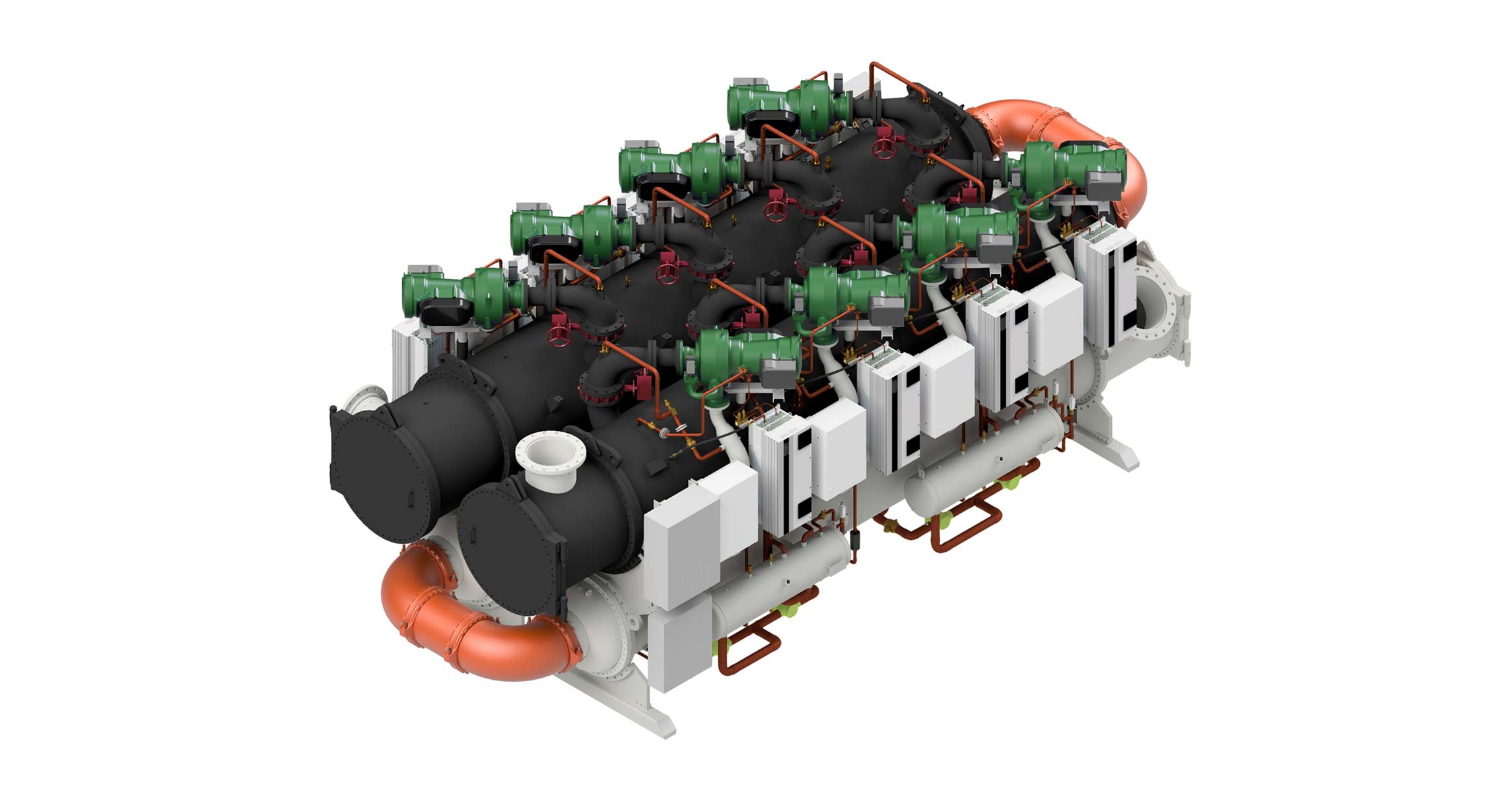

Why oil-free technology can reduce your environmental footprint

With the increasing pressure on businesses to reduce their environmental footprint, oil-free technology is emerging as an effective way to do so.

Here are the first three reasons why you should consider oil-free technology:

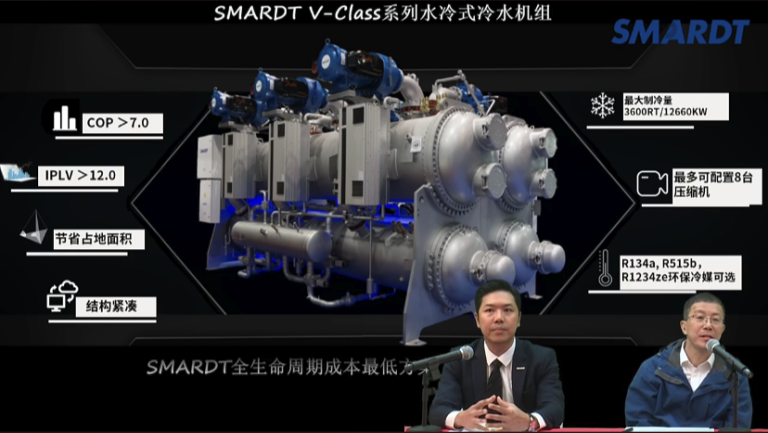

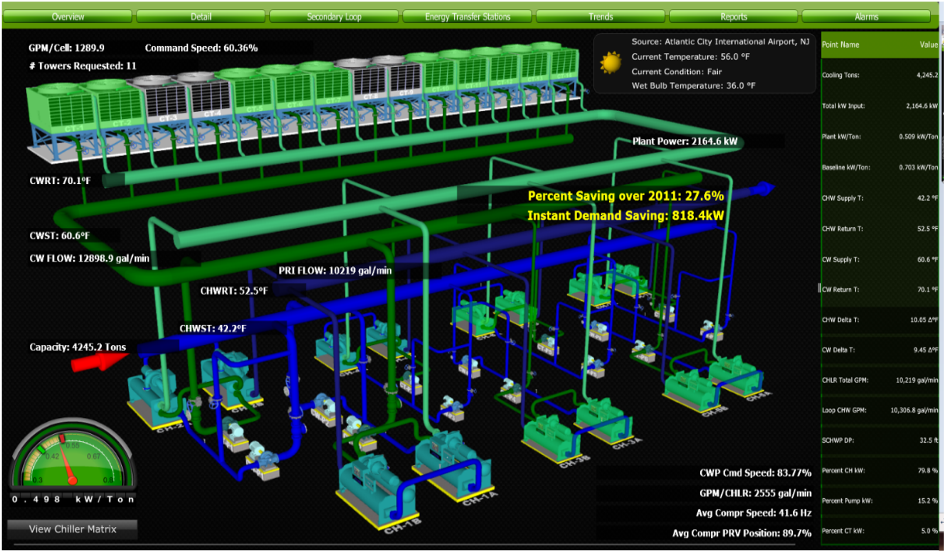

Reason #1: Energy efficiency: Oil-free chillers run on magnetic bearing technology, which reduces energy consumption by up to 40-50% over traditional chillers.

Reason #2 Reduce greenhouse gas emissions: The high energy efficiency of oil-free chillers translates into lower greenhouse gas emissions. Energy production, particularly from fossil fuels, is a leading source of greenhouse gas emissions. Oil-free chillers lower carbon dioxide and other harmful emissions.

Reason #3 No oil disposal: Traditional chillers use oil for lubrication, which needs to be regularly replaced and appropriately disposed of to prevent environmental contamination.

Reason #4 Less mechanical parts: Because oil is removed from the system, less maintenance, purchase, and storage of mechanical components are required to operate this type of equipment. This reduces waste and helps the environment as less material or resources are used.

Reason #5 Consistent performance: By eliminating oil, oil-free chillers provide reliable and sustainable performance throughout their lifecycle, which benefits the environment. Traditional chillers accumulate oil deposits over time, resulting in mechanical wear and excessive energy consumption.

Reason #6 Environmentally friendly: Oil-free chiller systems utilize environmentally friendly, non-flammable, and ultra-low refrigerants, which help easily meet government, state, or city carbon footprint expectations.

With global warming rising, it is more important to consider environment-friendly cooling solutions such as oil-free technology. Visit our main product page to learn more about our oil-free chillers product line: Products – Smardt Chiller Group Inc.