CPECS Optimization

CPECS provides true optimization for your chiller system and plant.

Kiltech offers three levels of CPECS to meet your needs.

CPECS Model A

CPECS Model S

CPECS Model T

Optimize your existing chiller system

Kiltech’s CPECS Model A gives owners and operators insight into their systems’ performance, and how that performance can be optimized.

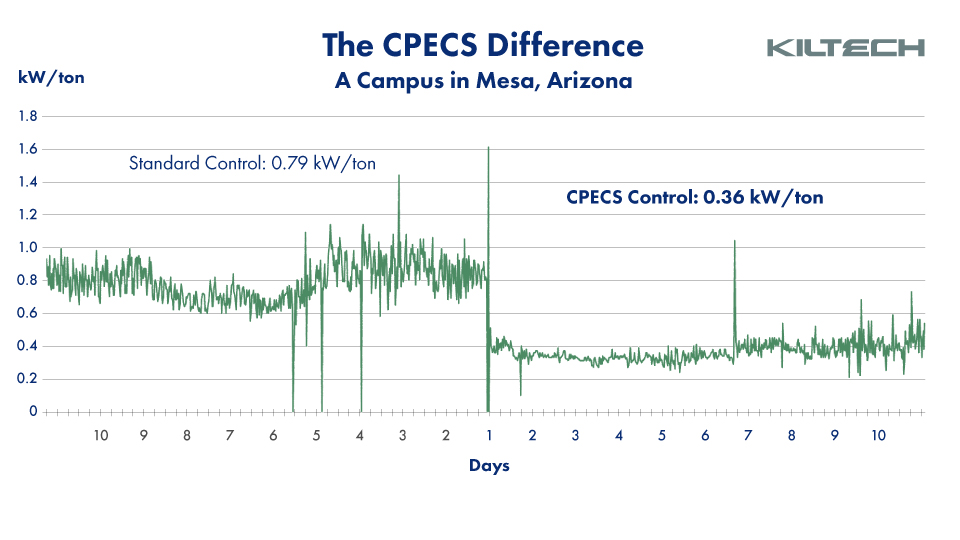

About CPECS

Central Plant Energy Control System (CPECS) is Kiltech’s system-based approach to provide chiller plant owners and operators ….

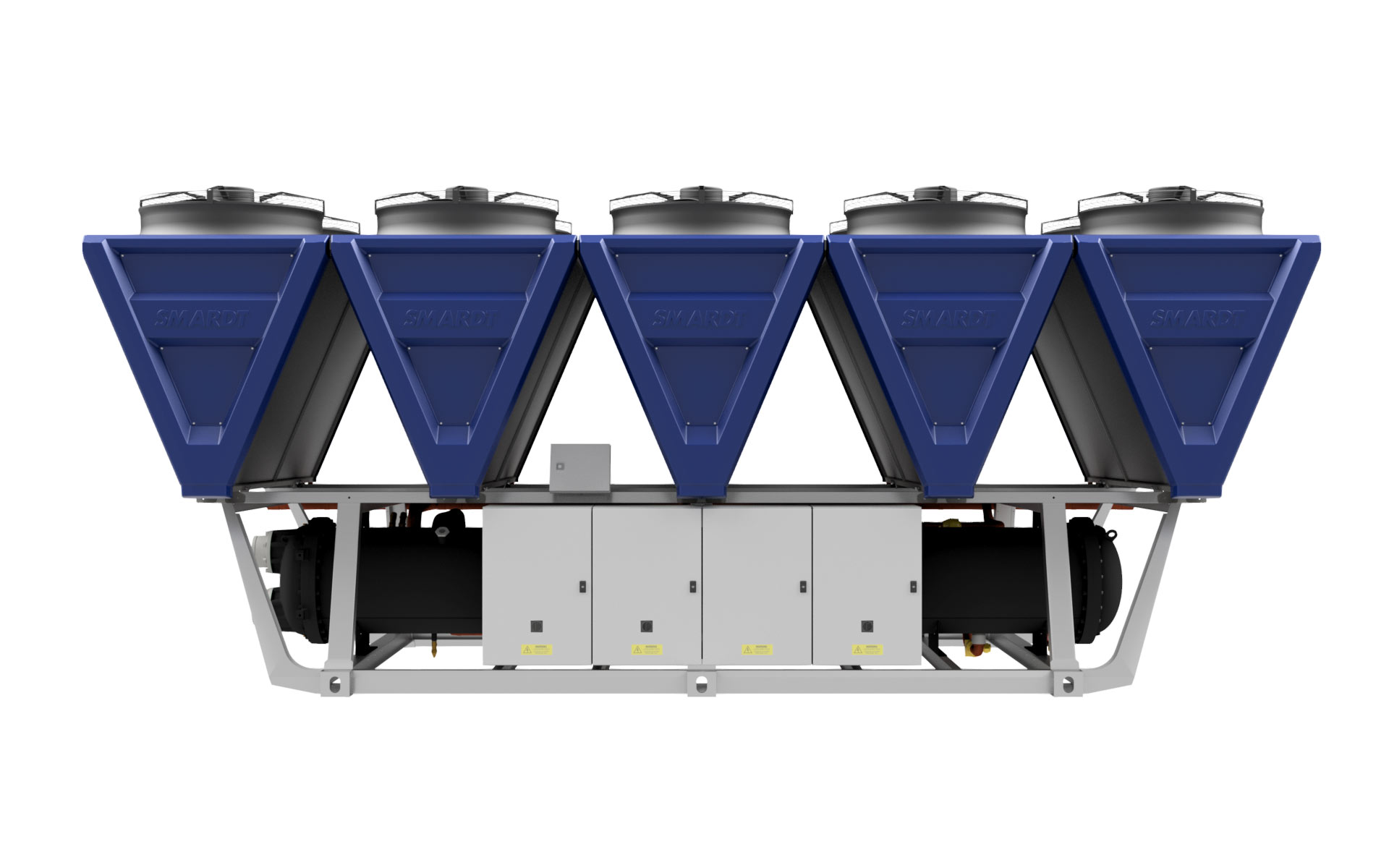

The Smardt TA-Class is ideally suited for installations where excessive noise is not permitted at certain times, such as residential neighborhoods at night. The system’s Active Noise Control feature allows you to limit the chiller’s sound output during specific periods of operation.

Status At A Glance

With each CPECS installation, Kiltech engineers build custom graphics that provide a visual snapshot of the actual plant room and system. Plant owners and operators see at a glance accurate representations of their equipment and the actual layout of their equipment, providing an overview of what’s currently running.

TA-Class is an optimal solution for applications requiring quiet, efficient cooling, for office towers, greenhouse facilities and data centers.

Key features and benefits:

- AHRI certified.

- Lowest life-cycle cost.

- 70% quieter than standard screw machines.

- More efficient than variable speed screws.

- V-coil configuration.

- Small footprint.

- Built-in compressor redundancy.

- Remote access.

- R134a, 513A, and R1234ze low GWP refrigerant.

- Optional CPECs for further plant optimization.

An abundance of cost saving measures

Older variable-speed screw chillers require a large footprint on the roof top. They are noisy and energy intensive.

Smardt TA-Class oil-free air-cooled chillers, by comparison are extremely quiet. They are also highly efficient, especially at part load. The result: lower power consumption when running your Smardt chiller.

Most Smardt customers realize immediate saving, with some Smardt installations actually paying for themselves within two years.

Your investment in any Smardt oil-free magnetic bearing chiller provides:

- Lower power consumption by 20 to 50%.

- Zero performance degradation.

- Smaller footprint: takes less real estate on your roof or plant room.

- Ease of installation: reduce cost on material and labor.

- Reduction in annual maintenance.

Want to rent Smardt chillers?

Contact a specialist to learn more about our rental services.