Press Release:

Dorval, Canada, Dec. 11, 2025 – Smardt is proud to announce the company has become a signatory of the United Nations (U.N.) Global Compact, a global corporate initiative for the advancement of responsible business practices.

With this voluntary pledge, Smardt joins thousands of companies who are committed to taking responsible business action and to creating a positive impact on the world.

«At Smardt, we believe sustainability and responsible business go hand in hand”, said Albert Yam, Chief Executive Officer of Smardt. “Joining the U.N. Global Compact reinforces our commitment to doing what’s right for our people, our customers and our business partners while contributing to the protection of our planet through innovative climate solutions. We’re thrilled to be part of this global corporate movement. »

This strategic alignment underscores Smardt’s resolve to support the UN Sustainable Development Goals (SDGs). By prioritizing on energy efficiency and decarbonization in the built environment, and by supporting communities in adapting to global warming through resilient social infrastructure, Smardt seeks to make measurable contributions to SDG 9 (Industry, Innovation & Infrastructure), and SDG 11 (Sustainable Cities & Communities).

As part of this commitment, Smardt will work on upholding the U.N. Global Compact’s Ten Principles which encompass human rights, labour, environment, and the fight against corruption. The company also pledges to publish an annual report detailing its ongoing efforts to embed the Principles in its strategy, culture, and day-to-day operations. This commitment will enhance Smardt’s existing disclosures pursuant to Canada’s Fighting Against Forced Labour and Child Labour in Supply Chains Act and to Australia’s Modern Slavery Act.

Launched in 2000, the U.N. Global Compact is the largest corporate sustainability initiative in the world, with more than 25,000 participant companies based in 167 countries.

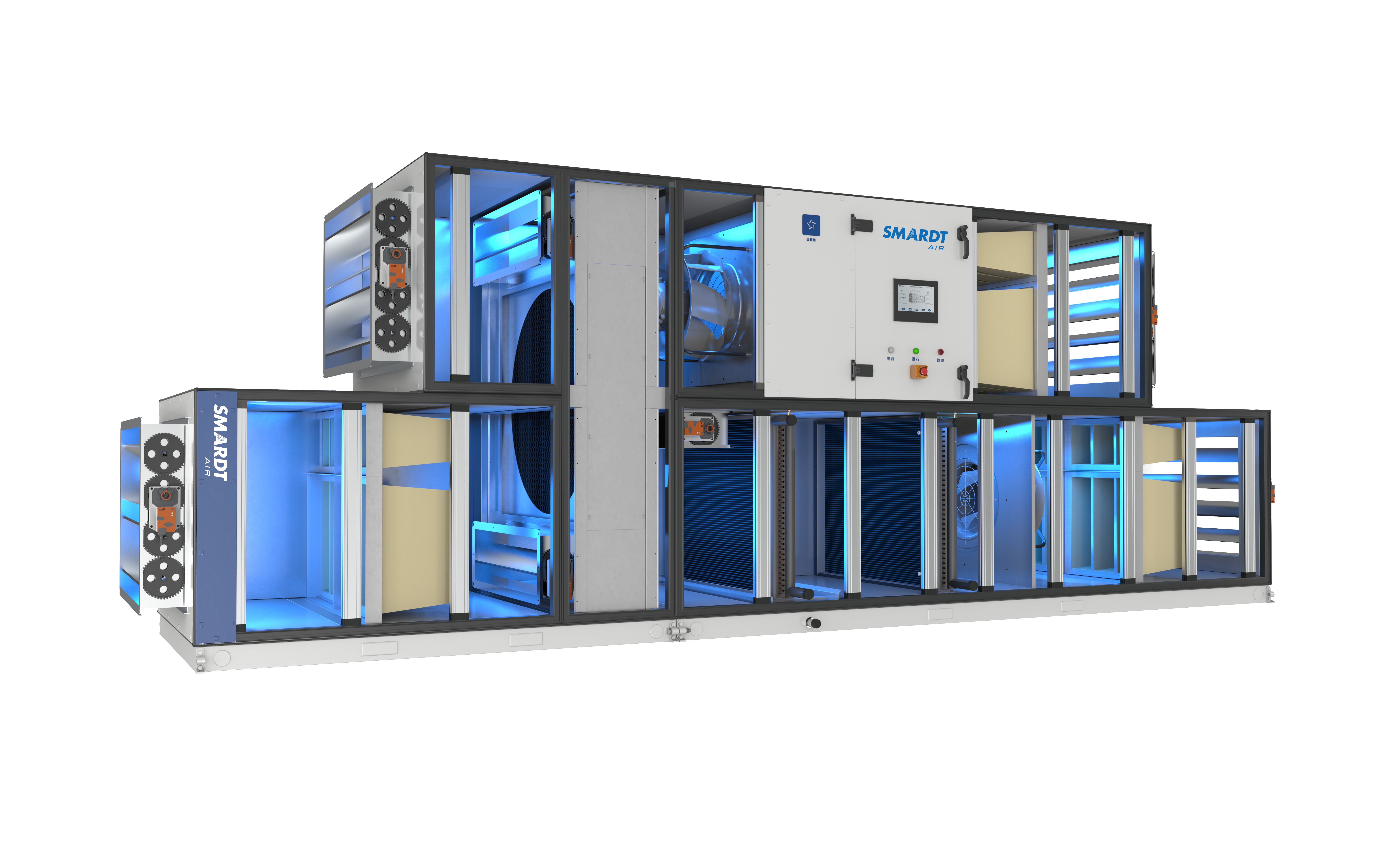

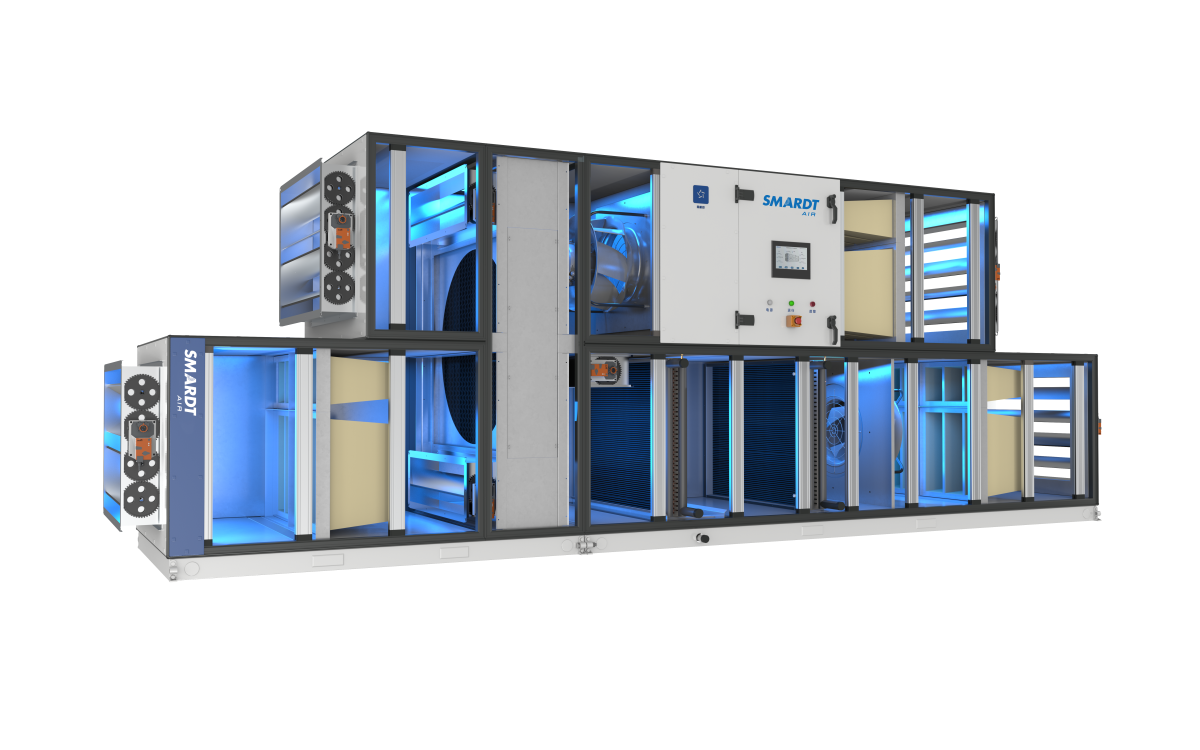

About Smardt

As a global leader in oil-free centrifugal chiller technology with an expanding portfolio of thermal management solutions, Smardt is dedicated to delivering high-efficiency and energy-saving systems for industries, real estate developments, health care and educational centers worldwide. We operate manufacturing facilities in the US, Canada, Germany, China, and Australia, with a team of over 900 employees. With a focus on reliability, performance, and environmental stewardship, Smardt continues to redefine industry standards through advanced engineering and a commitment to a more sustainable future.

Media Contact: