AeroPure, delivering reliably high operating efficiencies across a wide range of operating conditions.

Continue readingAeroPure

AeroPure, delivering reliably high operating efficiencies across a wide range of operating conditions.

Continue readingQuality Policy

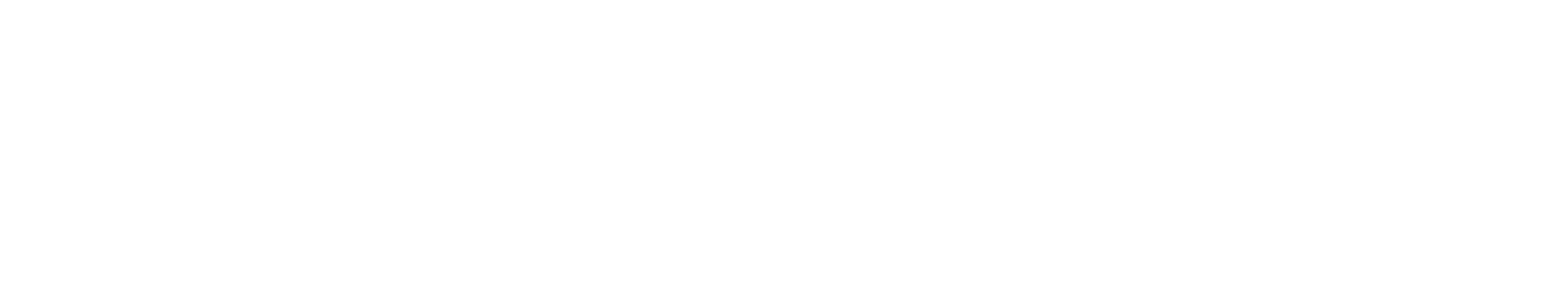

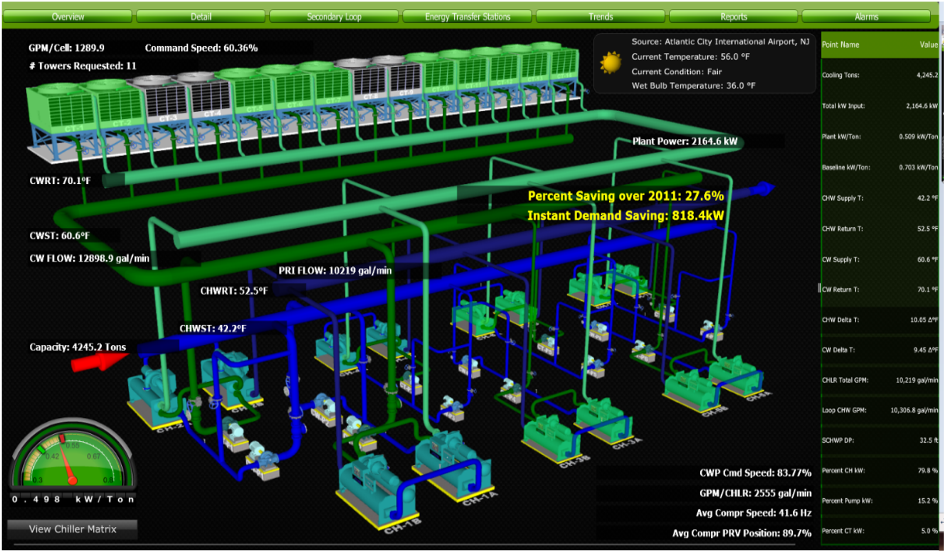

CPECS Optimization

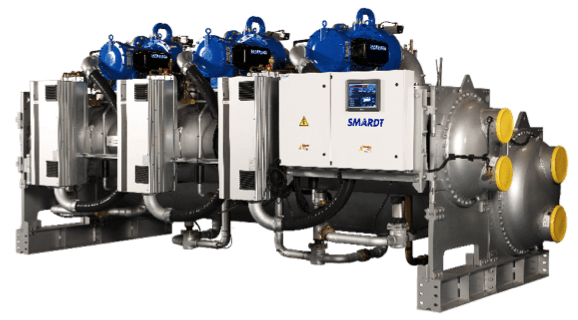

SSP (Smardt Special Products)

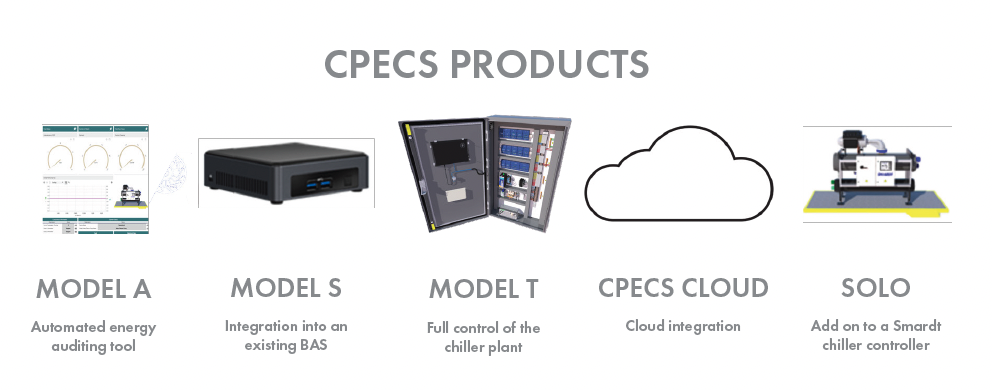

T-Class air-cooled

Ta-Class, delivering reliably high operating efficiencies across a wide range of operating conditions.

Continue readingE-Class

E-Class, Delivering reliably high operating efficiencies across a wide range of operating conditions.

Continue readingV-Class

V-Class, delivering reliably high operating efficiencies across a wide range of operating conditions.

Continue readingT-Class water-cooled

Tw-Class, delivering reliably high operating efficiencies across a wide range of operating conditions.

Continue reading