Museum of New Zealand Te Papa Tongarewa Plant Optimization & Chiller Upgrade

Situated on the Wellington Waterfront, the Museum of New Zealand Te Papa Tongarewa is a major icon in the capital city.

The impressive building, designed by Jasmax Architects, sits on 152 base isolators and is designed to protect occupants and collections from a one in 2000 year earthquake. Since opening in 1998, Te Papa has seen visitor numbers of around 1.5 million annually.

Client | Museum of New Zealand Te Papa Tongarewa |

Location | Wellington, New Zealand |

Industry | Arts and recreation |

Application | Office building |

Product | 2x 2000kW SMARDT WB190 Water Cooled Chillers |

The Goal

The central chilled water system in Te Papa was nearing end of life, with the chillers and cooling towers due for replacement. The original chillers utilized an obsolete refrigerant and were inefficient in comparison to modern chiller technology.

The client’s goal was to implement a chilled water system that maximized energy efficiency, reduced operational costs and provided an upgrade path which allowed for future transition to new lower global warming potential (GWP) refrigerants such as 1234ze.

The Challenge

A key challenge for this project was to provide two new high-efficiency chillers with a combined cooling capacity of 4000kW, while also lowering the pump power requirements of the system. In addition to this, the new plant needed to minimize the cooling tower water use and reduce legionella risk. The project also called for a chilled water plant optimization solution to ensure this solution operated at the maximum achievable efficiency.

zAs the building was still occupied during the revamp, the central plant needed to be upgraded and the optimization system integrated with the existing site building management system (BMS). Therefore, a collaborative approach towards commissioning and system fine-tuning was required while making sure the day-to-day running of this busy museum wasn’t impacted.

The Solution

The project incorporated a number of aspects, including:

- Reconfiguring the hydraulic system to transition from a constant primary / variable secondary configuration to a variable primary flow system which reduced pump power requirements.

- Replacement of the original cooling towers with closed-loop evaporative coolers for decreased water consumption, legionella risk and condenser water fouling potential.

- Installation and commissioning of a holistic chilled water optimization system to maximize plant efficiency.

- The client's focus on minimizing the lifecycle operation costs demanded high-efficiency chillers combined with a specialized central chilled water plant optimization system to ensure peak efficiency could be achieved in all operating conditions.

- A SMARDT Chiller solution with a CPECS Synergy Plant Optimization System was selected for this project due to the overall achievable efficiencies and ease of integration with the existing BMS.

Chillers

Two SMARDT WB190 2000kW Water Cooled Chillers were the ideal solution for this large application. These SMARDT Chillers utilize Turbocor® magnetic oil-free centrifugal compressors to achieve the highest IPLV energy efficiencies and lowest operating costs in their capacity ranges.

The SMARDT Turbocor® Chillers provided significant energy-efficiency improvement over the original R22 reciprocating chillers that were replaced.

A SMARDT Central Plant Energy Control System (CPECS) synergy optimization solution was incorporated to extract the maximum overall system efficiency from the upgraded equipment.

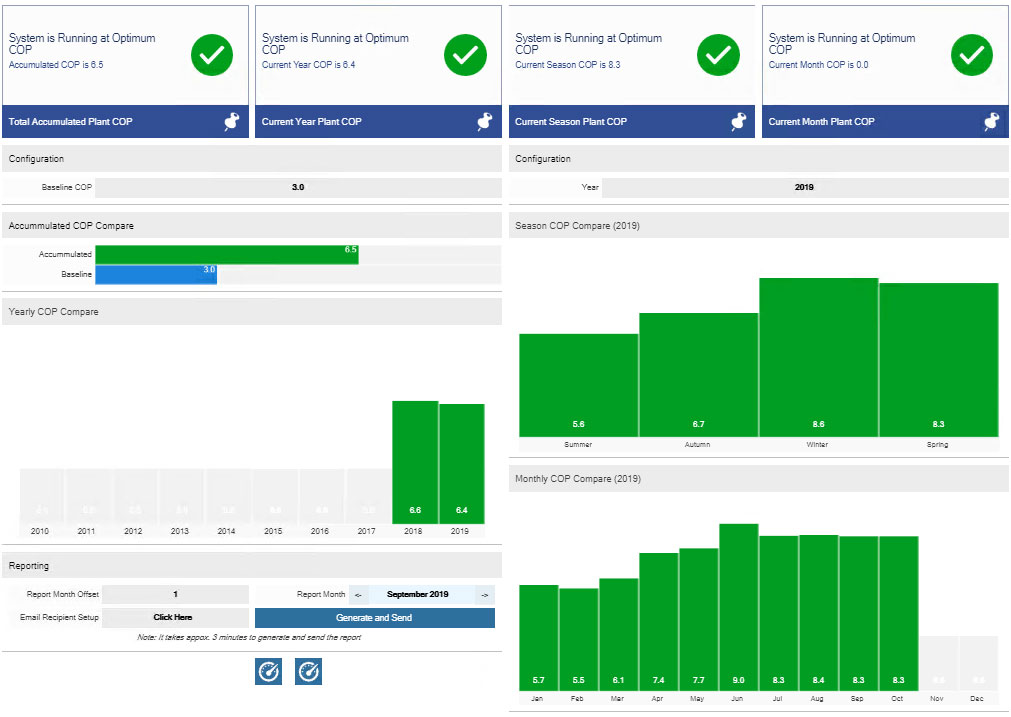

CPECS considers all aspects of the chilled water system and optimizes the chiller, cooling tower and condenser pump operation to achieve the highest Coefficient of Performance (COP) in real-time. CPECS goes beyond the traditional BMS control approach for a central chilled water plant, defining safe operating limits while extracting optimum system efficiency.

To achieve this, CPECS interacts with the existing Siemens Building Management System. The system constantly receives live operating data and provides optimized control setpoints for the BMS to target. The BMS then controls the field equipment to achieve the optimized speed and setpoint values.

In addition to the optimization aspect, CPECS also provides a platform for ongoing monitoring and verification of overall performance. The system is configured to provide automated performance reporting for the client on a monthly basis.

The Result

Te Papa has observed a significant reduction in building electricity load resulting from the upgraded chilled water system. Since May 2019, the CPECS monitoring and verification component has reported an average overall system COP of 6.0.

The overall plant COP calculation considers:

Total thermal cooling energy produced by the system,

Total electrical energy consumed by the system (chillers, cooling towers, condenser water pumps and chilled water pumps).