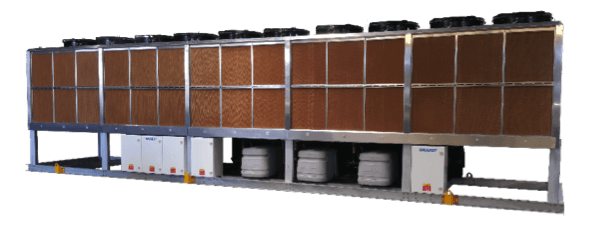

Revolutionary cooling for the hospitality industry

Smardt oil-free chillers can help your hotels garner 5-star reviews for financial performance.

Maximizes customer satisfaction and lowers energy costs with 35%-50% greater energy efficiency.

Energy is your next biggest operating cost after staff. And your guests can consume 40%-80% of that energy. Now, Smardt can help you pare your electric bill and add a real boost to your bottom line. Smardt chillers are oil-free. In conventional oil chillers, oil fouling can reduce system efficiency by 20% or more over time. In sharp contrast, Smardt oil-free chillers are equipped with levitating magnetic bearings. So there’s no metal-on-metal contact, or wear, and no oil fouling. The result? Energy savings of 35%-50%.

Cuts maintenance costs in half

Smardt chillers, being oil-free, have no need for bearing lubricant. By eliminating the lubrication system and its many moving parts, Smardt gets rid of a major maintenance headache. Servicing lubricated oil chillers requires significant labor, time, and a costly inventory of replacement parts. With the lubrication system gone, Smardt oil-free chillers can reduce maintenance costs up to 50%.

Precision control

A J.D. Power survey shows that one of the biggest complaints among hotel guests is being too hot or too cold. The Smardt oil-free chiller’s precision control system can help facility managers provide optimal room temperature throughout a hotel.

The Smardt controller is user-friendly and highly intuitive. The compressor’s onboard digital controller proactively manages compressor operation, allowing external control and web-enabled performance monitoring. By maximizing time spent operating at compressor “sweet spots,” the Smardt controller reduces power consumption while providing flexible operation.

Efficient at both full and part-load

Many hotels have taken a financial hit as the pandemic has put a damper on travel. As business ramps up again, Smardt oil-free chillers can handle the greater load, while keeping your energy costs low.

Algorithms in the system controller optimize compressor part-load efficiency. Smardt’s integrated part load values (IPLV) are better than those oil-lubricated, reciprocating, scroll and screw compressors. The Smardt oil-free chiller’s load can be adjusted to accommodate everything from no guests (e.g., during off-season or renovation) to full occupancy.

Smardt Cool means more cost savings

When the ambient temperatures are low, Smardt oil-free air-cooled chillers can shut down the system compressors. Only the fans continue to run. In this way, Smardt’s advanced Smardt Cool feature uses the refrigerant’s thermodynamics to provide chilling. Naturally, running with the compressors off is extremely energy efficient.

Starting current for the Smardt oil-free chiller’s compressors is as low as 2 amps. So We sidestep extreme current draws to bypass peak tariffs.

High reliability

Smardt oil-free chillers have multiple redundant compressors, which ensures high system availability. If a compressor goes offline, the remaining compressors continue running—and the chiller continues to cool. In the event of a power failure, Smardt’s advanced Fast Restart feature can get the downed compressor back online in less than 90 seconds.

Features and benefits

- Efficient at full and part-load

- No oil. Low maintenance

- Precision control

- Low starting current

- Smardt Cool options available

- Lowest total cost of ownership