The global leader in oil-free chillers.

Smardt’s team has over 25 years of experience in oil-free chillers with more than 10,000 units installed worldwide.

Improved chiller efficiency.

20% to 50% greater energy efficiency vs. oil-lubricated chillers.

Oil-free.

Magnetic bearings eliminate the need for lubrication, reducing both maintenance requirements and total cost of ownership.

The global leader in oil-free chillers.

Smardt’s team has over 25 years of experience in oil-free chillers with more than 10,000 units installed worldwide.

Improved chiller efficiency.

20% to 50% greater energy efficiency vs. oil-lubricated chillers.

Oil-free.

Magnetic bearings eliminate the need for lubrication, reducing both maintenance requirements and total cost of ownership.

0

+ oil-free chiller installations worldwide

Revolutionary cooling solutions from Smardt

The global leader in oil-free centrifugal chillers

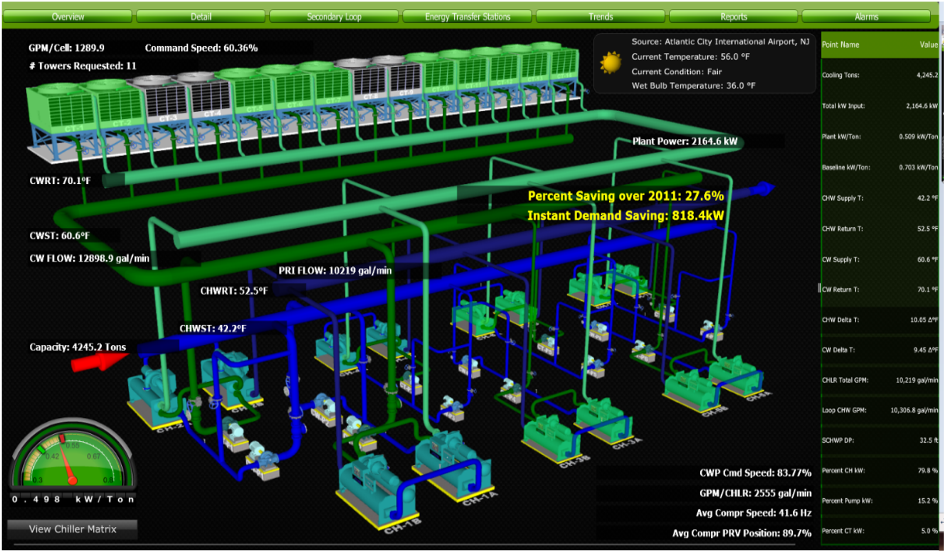

Smardt, the global leader, offers you the most comprehensive and customizable line of air, water, and evaporatively-cooled oil-free chillers. Advanced features and custom engineering allow us to tailor and optimize our oil-free chillers for all industry and facility needs. So you and your customers stay productive, safe, and comfortable.

Smardt guarantees consistent and reliable oil-free chiller performance. Energy efficiency is 20% to 50% greater than oil-lubricated chillers. Eliminating lubrication systems reduces maintenance costs by 50% or more. Result: a superior ROI and an improved environmental footprint with no oil contamination.

Major-league performance.

The NFL counts on consistent and ultra-reliable cooling from Smardt oil-free chillers to preserve its sports film library—the world’s largest.

Fast, reliable local support on a global scale.

Quick service where and when you need it for maximum system availability.

Get the Smardt oil-free chiller advantage

- Over 25 years of industry-leading experience and expertise.

- Standard, semi-custom, and custom oil-free chillers.

- Advanced features maximize efficiency and give you full control.

- Consistent performance with loads up to 3,600 tons (12,66 MW).

Smardt oil-free chillers

The intelligent choice for your facilities.

Smardt oil-free centrigufal technology drives chiller system cost savings across the world, probably somwhere near you

Smardt oil-free chillers

The intelligent choice for your facilities.

Smardt boasts the industry’s most comprehensive and customizable product line. That means Smardt can design, build, and install the optimal oil-free chiller—a perfect fit for your building specifications, temperature requirements, application, and industry.

Quiet operation, significant energy savings, and exemplary indoor environment for both guests and staff.

Quiet operation, significant energy savings, and exemplary indoor environment for both guests and staff.

Hotels

Hospitals

Data Centers

Government

Manufacturing

Schools & Universities

Office Buildings

Greenhouses

Naval & Marine

Pharmaceutical

Smardt chillers are 100% oil-free.

At Smardt, we make oil-free chillers. Nothing else. Manufacturing and supporting oil-free chillers has been our sole business for over 25 years. So when you rely on Smardt, you’re dealing with the leading experts in oil-free chiller technology.